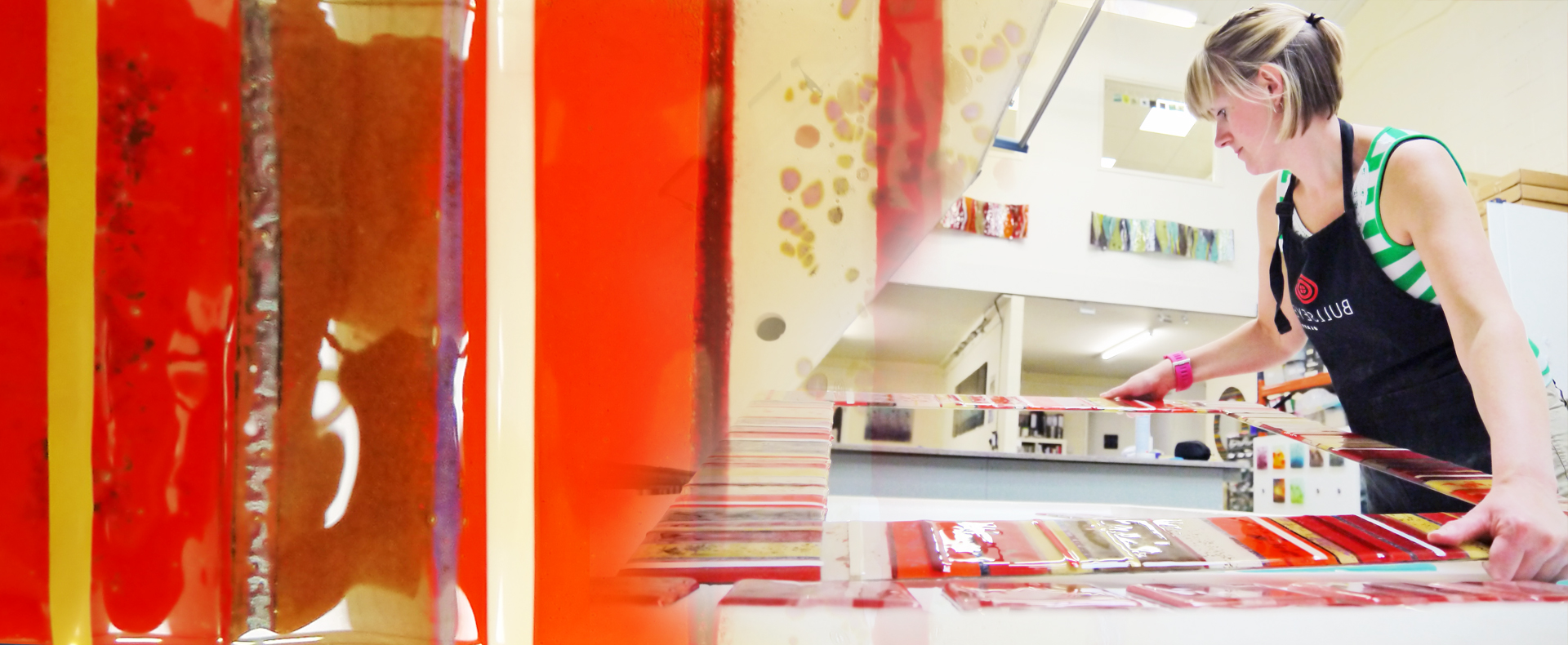

How our fused glass is made

Fused glass technique

Layers of glass powders, sheets of glass, foils and glass grains all combine to create beautiful effects within our fused glass. Designs are layed out onto sheets of glass and the materials are built up in layers to produce the overall look that your pice of fused glass will have. The fusing process involves applying heat to the finished creation in order to combine all the components together creating our fused glass.